Full digitisation

of the production process for cutting, folding and beyond!

Lorem ipsum dolor sit amet,

consectetur adipiscing elit.

Lorem ipsum dolor sit amet,

consectetur adipiscing elit.

Lorem ipsum dolor sit amet,

consectetur adipiscing elit.

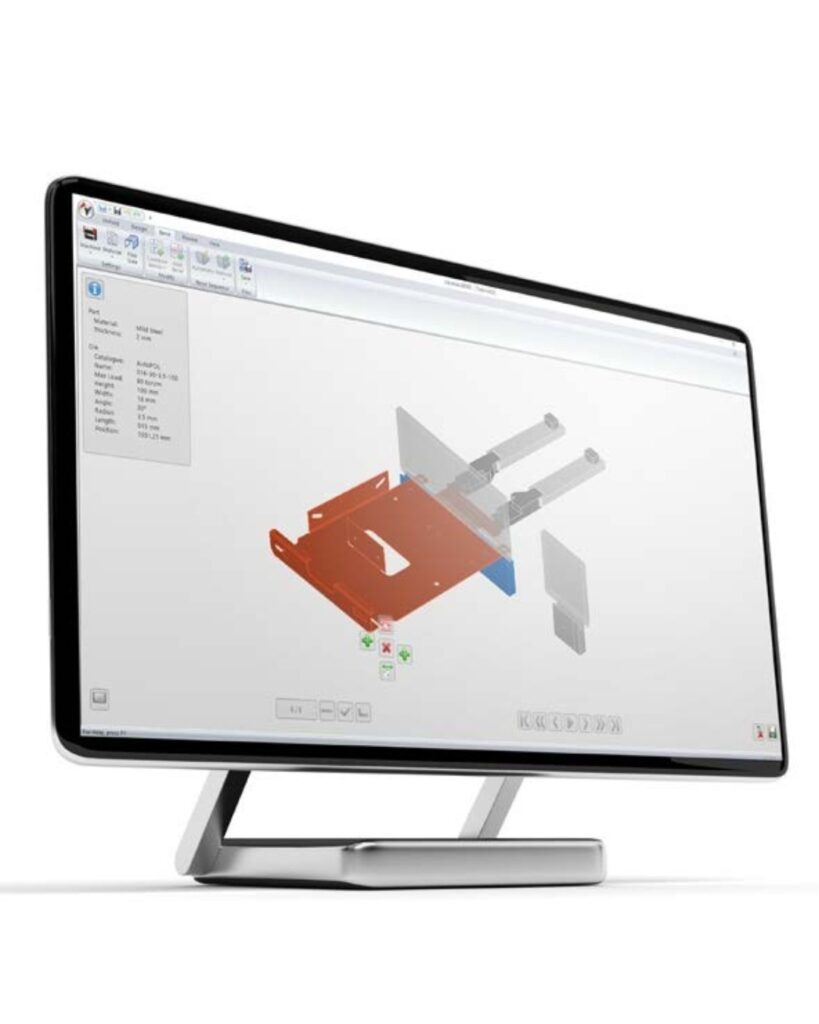

JobSHOP by Libellula is the integrated system developed by Libellula for comprehensively and intelligently digitise the production process in laser cutting and bending, even in the presence of any secondary work cycles.

It is designed to manage every operational step, from job generation, through the automatic preparation of machine programmes, intelligent multi-machine queue management, to real-time production data collection, according to the requirements of theIndustry 4.0.

JobSHOP by Libellula is the pack that integrates some of the best Libellula software that intervenes synergistically at every stage of the process to support management, technicians and operators in decision-making and programming, ensuring that the highest possible levels of efficiency are achieved, and preserving production time and costs.

The system includes all the necessary modules for

La generation and traceability of orders through mod.ORDER

L'programme queuing machine via mod.MANAGER

The real-time monitoring of the work progress and detection of incorrect parts or rejects of production thanks to the MES of Libellula, Libellula.VISIO

Depending on the system used, Libellula.JOBSHOP integrates with the native Libellula CAM software:

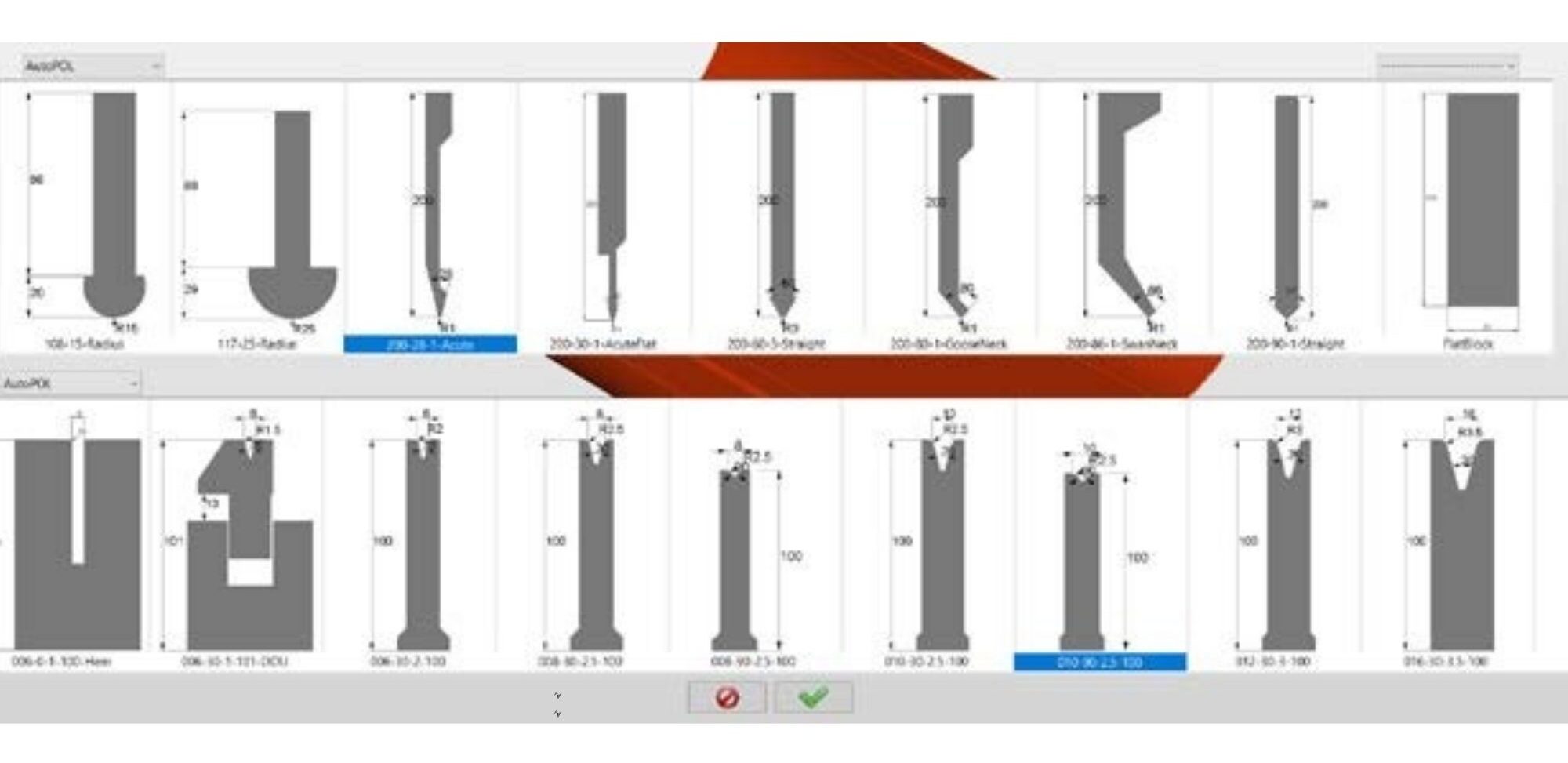

Libellula.BEND enables off-line configuration and programming of press-bending machines, ensuring

Reduced downtime thanks to offline programming

Intuitive interface for quick and easy programming

Assisting the operator in tooling and bending sequence calculation

Eliminating production errors and improving productivity

Integration with mod.ORDER for the management of cutting orders and any subsequent work cycles

Thanks to its modular and scalable architecture, JobSHOP by Libellula is perfectly adapted to the needs of every company, regardless of its size or production complexity. In addition to order management and production, you can rely on efficient functionalities and applications to digitise the entire production cycle: transforming your company into a Smart Factory has never been easier!

With mod.STORAGEit is possible to track the availability of raw materials, standard sheets and reusable scrap, castings and raw material locations in real time, optimising resources and reducing waste.

The quotation Libellula.QUOTATION makes it possible to quickly generate precise, customised offers for the customer, based on real cutting, bending and secondary processing data, increasing competitiveness and reducing time-to-quote.

Libellula.SORTING simplifies and speeds up the entire unloading process. Perfectly integrated with the CAD/CAM Libellula.CUT, Libellula.SORTING gives all icons, or a group of them, a unique colour depending on a number of parameters such as order or customer. Thanks to this colour code, it will be almost a game for the employee in the department to recognise the parts to be unloaded, eliminating any errors.

Libellula.JOBSHOP is designed to be integrated with major systems ERP to ensure a continuous, two-way flow of data: from order management, to production planning, to warehouse and scrap control, for a full traceability e consistency between technical, administrative and production departments.

Digitise folding with ease

Perfect for increasing precision and speed.

More efficiency, less waste, maximum control.

Excellent for variable batches and multi-machine plants.

Bending linked to corporate strategy

Smart management from quotation to ERP.

Every piece of data becomes part of the strategic vision.

For those who want high performance and continuity between office and production.

Search for the

most suitable product for technology you use.

Come and discover the world of JobSHOP packs

signed Libellula.

WALLAIR raises efficiency with Libellula.JOBSHOP ecosystem: the vanguard of Smart Factory 4.0 WALLAIR, a benchmark in the production of components for the demanding aerospace industry,...