Lorem ipsum dolor sit amet,

consectetur adipiscing elit.

Lorem ipsum dolor sit amet,

consectetur adipiscing elit.

Lorem ipsum dolor sit amet,

consectetur adipiscing elit.

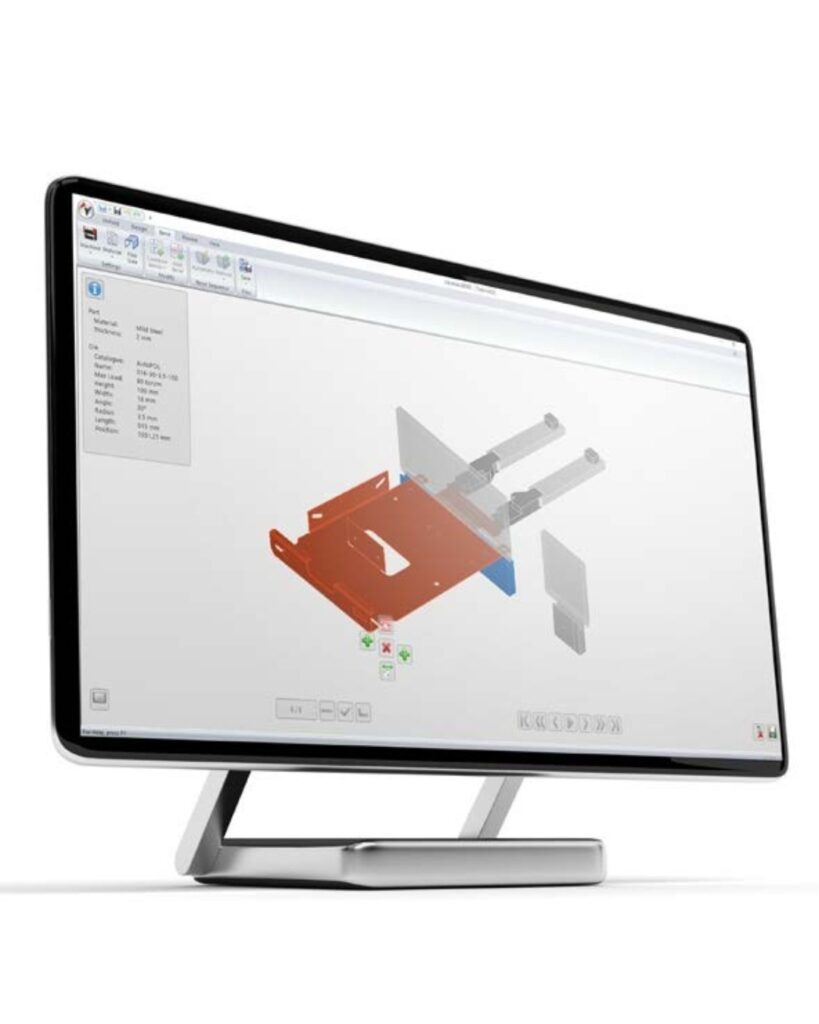

Thanks to the offline programmingdrastically reduces downtime, increasing productivity in the workshop.

In line with the philosophy Zero-Training of the Libellula, the Libellula.BEND offers a simple and intuitive interface, enabling even less experienced personnel to prepare accurate and reliable bending programs, with step-by-step assistance in tooling, calculating the optimal sequence and positioning the stops.

Traditional bending software requires on-machine testing, which wastes material and time because the machine remains busy testing instead of producing. With Libellula.BEND, simulation takes place in the 3D environment, without consuming material and keeping the machine free to work, thus safeguarding productivity and meeting deliveries.

Offline programming also prevents potential production problems, reducing waste and unscheduled downtime.

It imports 3D (STEP, ACIS) or 2D (DXF) models, recreates the three-dimensional model and generates the unfolding taking the tool magazine into account.

It calculates the optimal bending sequence, checking collisions and optimising movements, rotations and displacements.

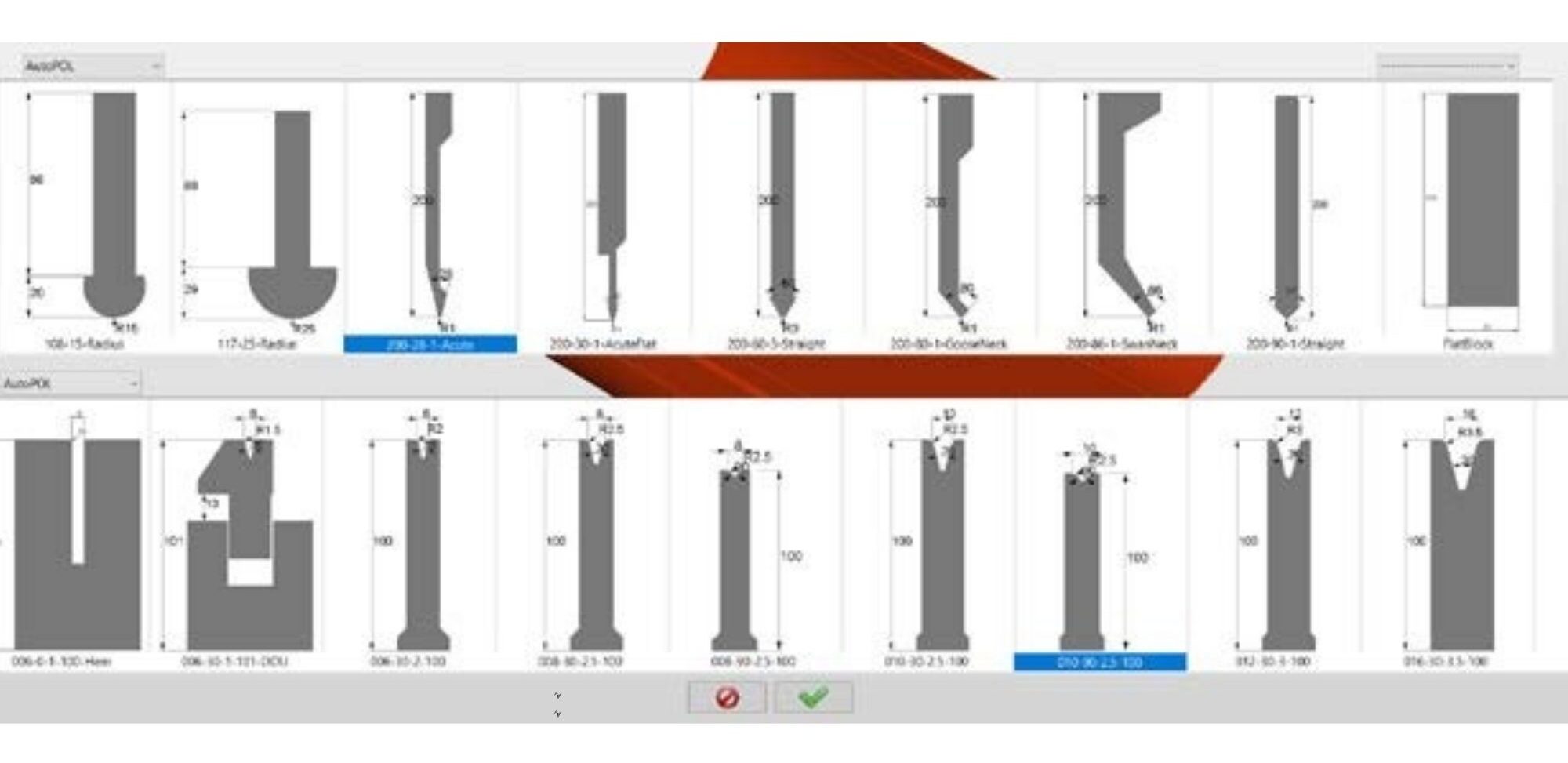

It automatically assigns punches and dies available in stock, according to machine specifications.

It allows the bending process to be simulated before actual production, avoiding errors and waste.

Libellula.BEND combines power and simplicity to eliminate shop floor downtime, improve quality and reduce errors. It is the ideal tool for those who want to digitise bending with precision, safety and speed.

Search for the

most suitable product for technology you use.

Come and discover the world of JobSHOP packs

signed Libellula.

JKF, based in the northern part of Denmark, is a company specialising in the development and production of complete industrial vacuum systems, such as filters, separators,...