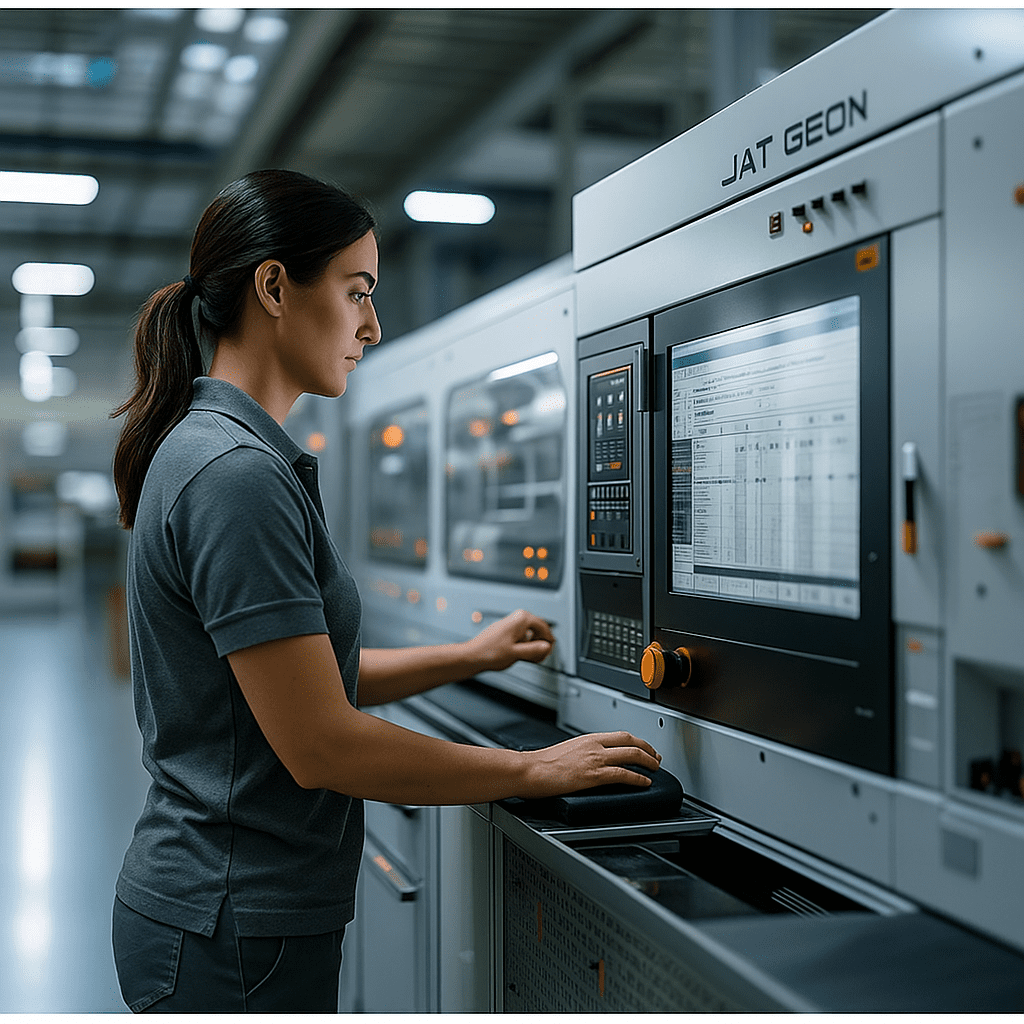

Libellula for production control.

Flexibility, continuity, total automation.

Libellula manages and coordinates every stage of industrial production, from warehouse to department, for a smooth, precise and integrated supply chain.

This family of software products is designed for companies wishing to optimise their production processes by having real-time control of all activities taking place on the shop floor.

mod.MANAGER is the system for the dynamic management of machining queues on CNC systems, bending machines and secondary processing. Perfectly connected with the technical department and MES VISIO, it optimises machine utilisation, eliminates conflicts and monitors each phase in real time.

mod.ROUTING introduces advanced management of machining cycles, automating repetitive tasks and tracking each process precisely. Ideal for serial and integrated machining, it is the basis for standardised, high-performance production.

Libellula.VISIO is the central MES for the entire production system: it plans, controls and optimises every machine and resource on the shop floor, with a single, intuitive interface that digitises production in an Industry 4.0 way.

Libellula.SORTING speeds up the unloading of parts with a visual colour system that guides operators, eliminates errors and integrates information with cutting and production for immediate traceability.

Libellula.STOCKER automates the sheet metal warehouse: recognises, picks, moves and updates stock status in real time, without manual intervention. It is the key to a continuous and uninterrupted production flow.

mod.STORAGE completes warehouse management with precise control over sheet metal, special formats and off-cuts. Every movement is tracked, every stock automatically updated, to reduce waste and optimise consumption.