Sicam PUNCH

Total control of CNC punching,

from geometry to the machine programme.

Lorem ipsum dolor sit amet,

consectetur adipiscing elit.

Lorem ipsum dolor sit amet,

consectetur adipiscing elit.

Lorem ipsum dolor sit amet,

consectetur adipiscing elit.

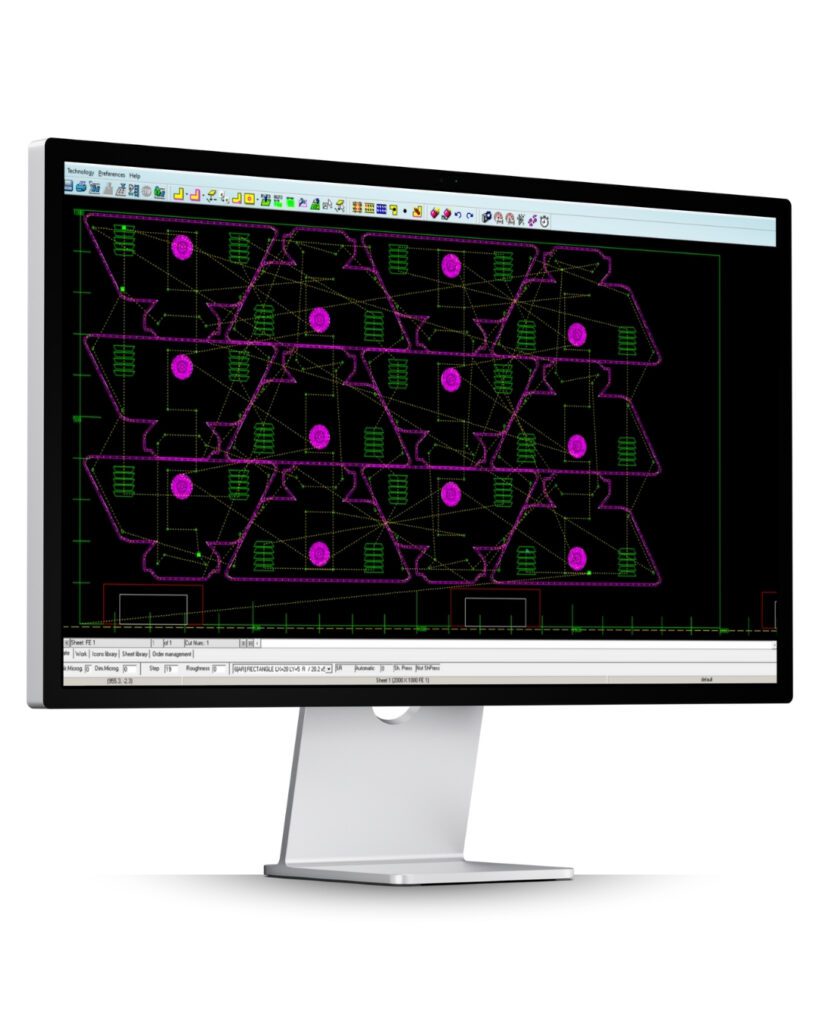

Sicam PUNCH is the CAD/CAM developed to comprehensively and intuitively manage the programming of punching machines numerical control.

With a platform designed to offer flexibility, precision and speed, it transforms every stage of preparation into a streamlined and reliable process.

In a single integrated environment, the operations person has access to advanced drawing, nesting and application technology tools, with the certainty of obtaining optimised and ready-to-use machine programmes.

Technical description

Integrated 2D CAD with profile optimisation

The internal CAD environment allows the creation and editing of 2D geometries with specific tools for automatic profile cleaning, speeding up the drawing preparation phase and minimising errors.

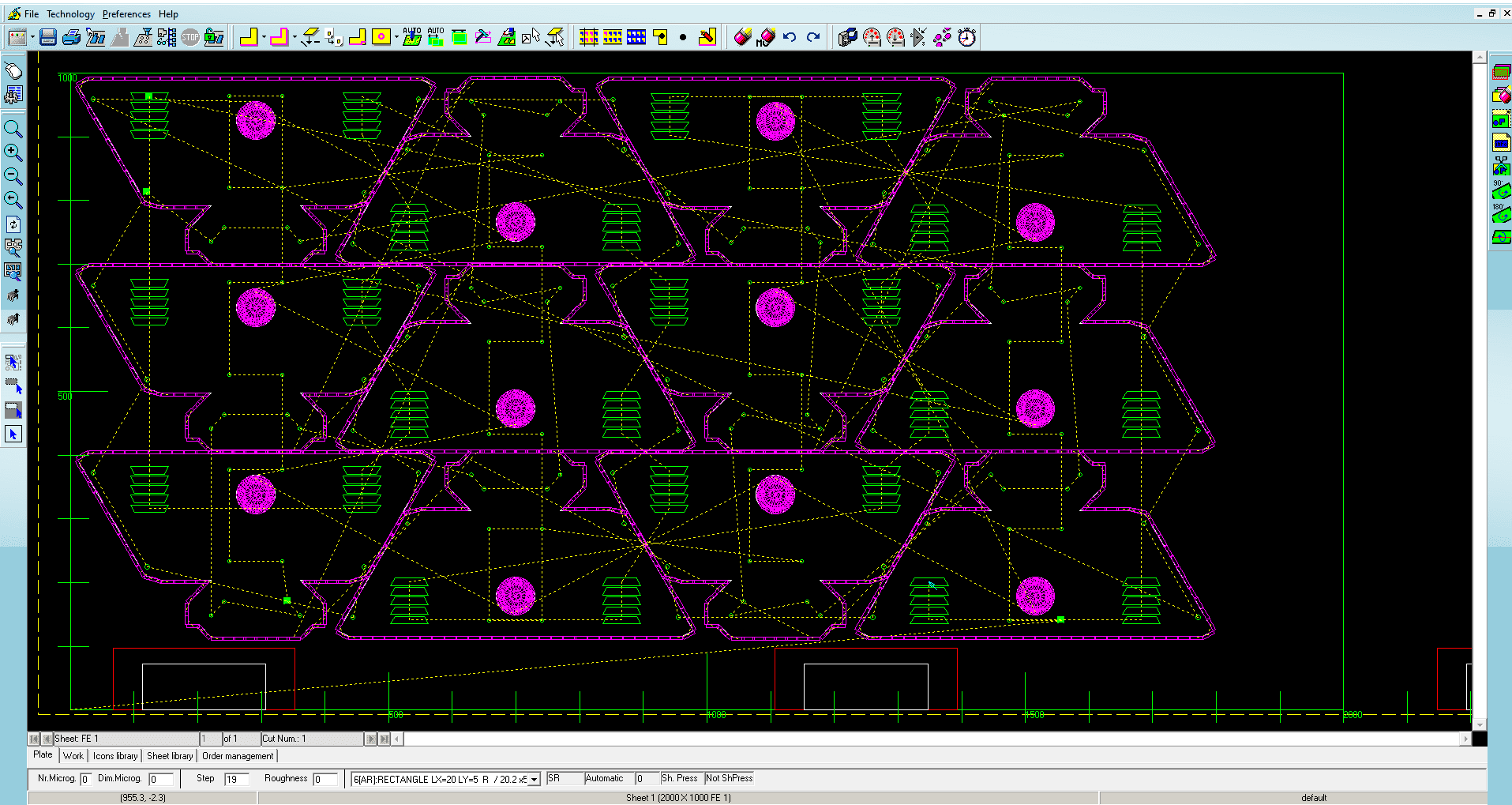

Advanced manual and semi-automatic nesting

Part layout optimisation can be done manually (with keyboard shortcuts for quick handling) or in semi-automatic mode. The aim: to reduce material waste and optimise machine time.

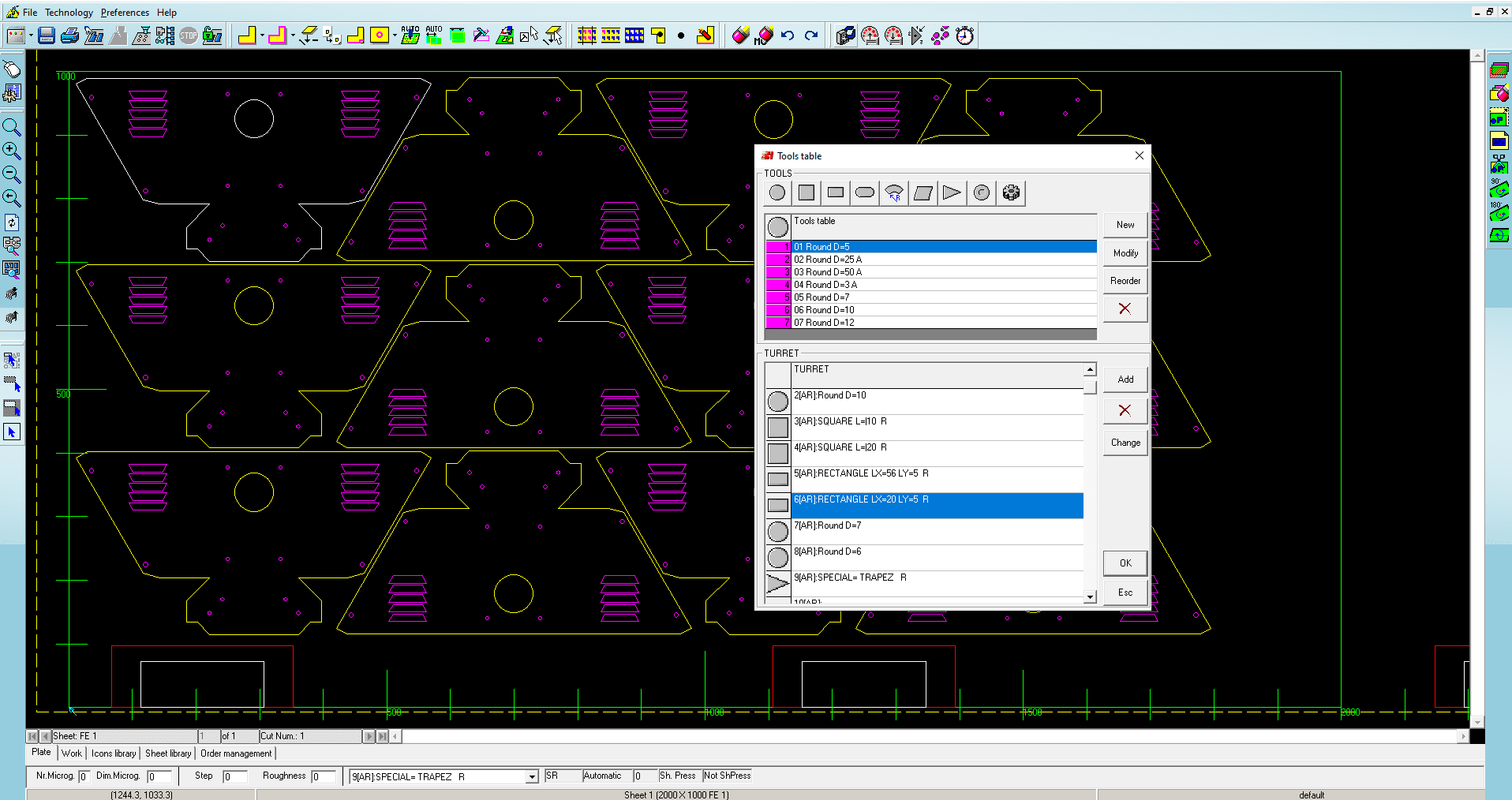

Automatically applied technology

Depending on the tools available on the machine, SICAM [punch] applies machining technologies automatically or manually. It includes the complete management of nibbling, hatch unloading and advanced strategies for complex geometries.

Complete output: programmes and reports

Once the preparation is complete, the system automatically generates CNC-compatible programs and detailed reports, ensuring fast, traceable and error-free data transfer.

The internal CAD environment allows the creation and editing of 2D geometries with specific tools for automatic profile cleaning, speeding up the drawing preparation phase and minimising errors.

Advanced manual and semi-automatic nesting

Part layout optimisation can be done manually (with keyboard shortcuts for quick handling) or in semi-automatic mode. The aim: to reduce material waste and optimise machine time.Automatically applied technology

Depending on the tools available on the machine, Libellula.PUNCH applies machining technologies automatically or manually. It includes full management of nibbling, hatch unloading and advanced strategies for complex geometries.Complete output: programmes and reports

Once the preparation is complete, the system automatically generates CNC-compatible programs and detailed reports, ensuring fast, traceable and error-free data transfer.

Main advantages

Learn more

Reducing preparation time

Automated and optimised processes speed up every step from design to nesting.

Maximum precision and optimisation of tool paths

It guarantees high cutting quality and error reduction thanks to intelligent machine movement management.

Greater efficiency in material utilisation

Advanced nesting allows optimal use of the sheet metal, minimising scrap.

Seamless integration with the Libellula suite

It is part of a complete CAD/CAM ecosystem designed for smooth, interconnected manufacturing.

Adaptability to any type of plant and production logic

It can be configured according to the specific production and technical needs of the company.

Sicam PUNCH is also prepared for:

- Working with geometries from standard CAD formats (e.g. DXF, DWG).

- Integrating drawing and nesting tools within a single operating environment.

- Supporting complex technologies such as nibbling and automatic unloading.

- Generate complete outputs for fast and traceable data transfer to the CNC machine.

Search for the

most suitable product for technology you use.

Come and discover the world of JobSHOP packs

signed Libellula.

Who chooses Libellula

DUMACO

Dumaco was founded in 2017 as an acronym for 'Dutch Manufacturing Companies' and today represents a solid and structured entity in the machining...